BEST-SCII (Semi-Automatic Cross Hemming Machine)

Supporting Automation and Labor-Saving in Towel Hemming.

BEST-SCII supports a wide range of towel types and designs, making it suitable for small lot and multi production.

It enables the creation of uniform and beautiful hems regardless of skill level or experience.

Furthermore, it achieves a complete three-fold hemming mechanism that our previous models couldn't realize. It brings the finish closer to hand-sewn quality.

| Model: | BEST-SCII |

|---|

Function

-

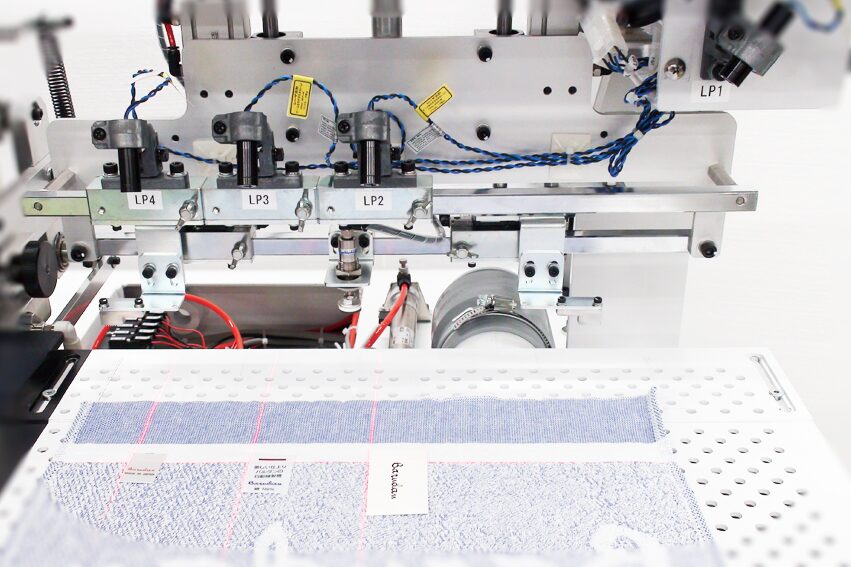

01. Towel Setting Section

-

The line between the flat areas and pile areas of the towel can be aligned by hooking it onto the edge of the table. Additionally, a laser marker line is projected as a guide for the sewing position

The set towel is held in place by air suction to prevent moving

Once the setup is completed,he towel sides are stretched and stabilized by the stretching device.

-

-

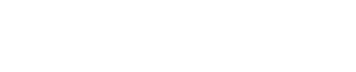

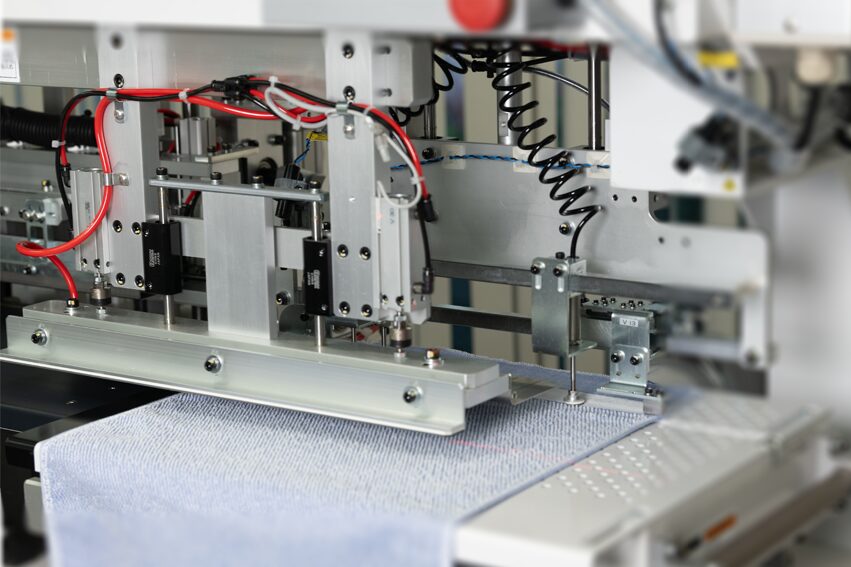

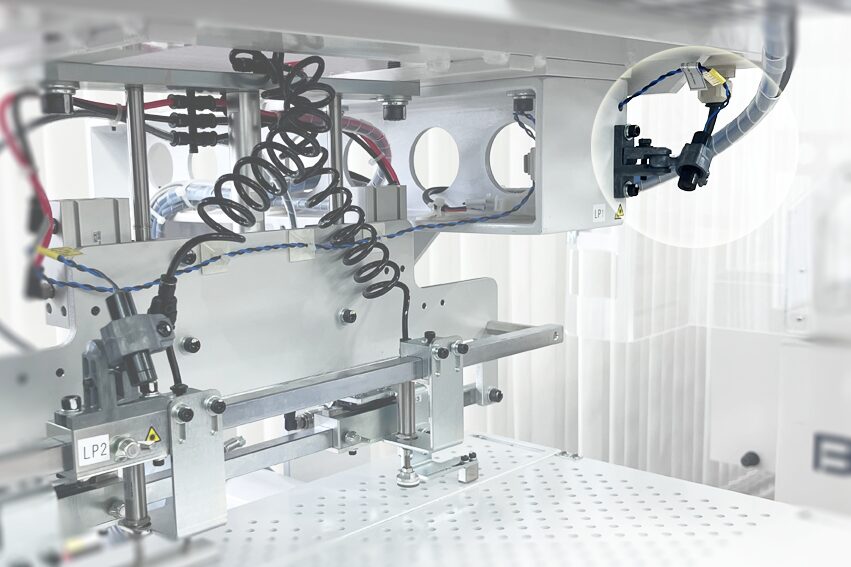

02. Transport Section

-

The towel pressing part of the transport mechanism uses a keyboard-type presser to absorb the difference in height between the towel side and the flat area.

The machine is equipped with a first transport mechanism that moves the towel from the set table to the three-folding mechanism, and a second transport mechanism that moves the towel from the three-folding mechanism to the sewing mechanism.

-

-

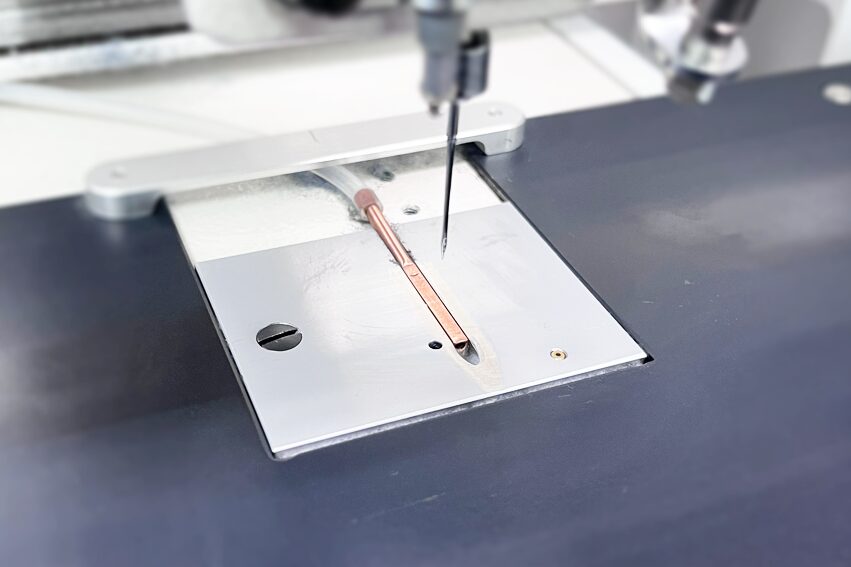

03. Complite Three-Folding Mechanism

-

This mechanism is for automatically performing three-fold hemming.

By adopting a rotary three-fold mechanism, it supports hems rang from minimum of 10mm to maximum of 50mm. The hem width can be easily adjusted manually using a hand crank.

-

-

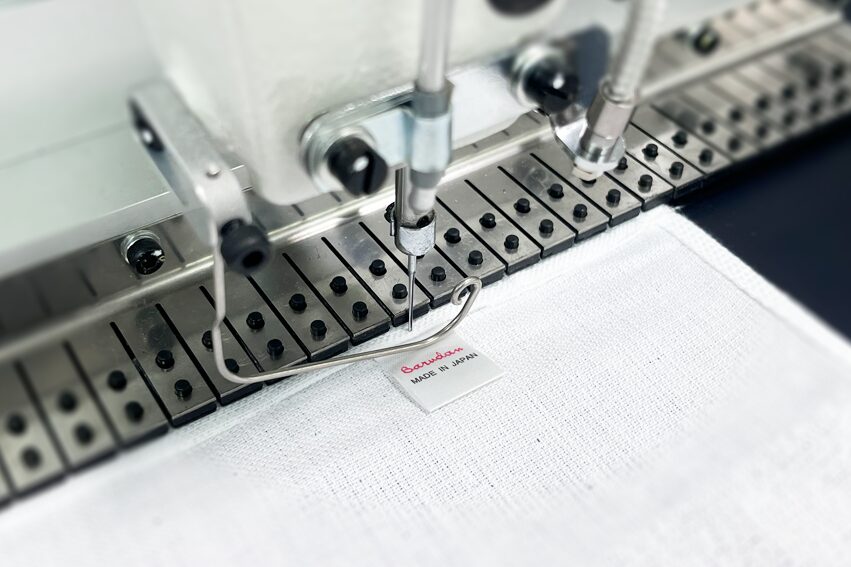

04. Sewing Section

-

This mechanism automatically sews folded hems.

The sewing clamp that holds the towel uses a keyboard-type presser.

It adjusts to thickness and height differences according to the towel's thickness, preventing shifting and ensuring uniform stitching.

An air blow system is embedded in the needle plate to prevent pile from being caught in the stitching.

-

-

05. Stacking Mechanism

-

Finished toerld are collected using a dedicated hanger.

-

Machine Specifications

-

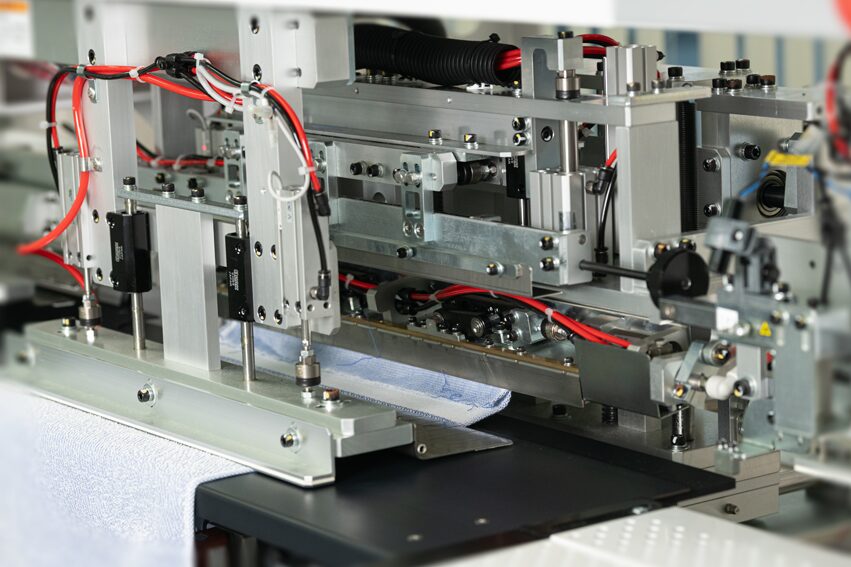

Laser Maker for Towel-Set Position

-

Laser Maker for Label Position ※ for one label position

-

Label Presser

-

Air Blower for the Sewing Section

-

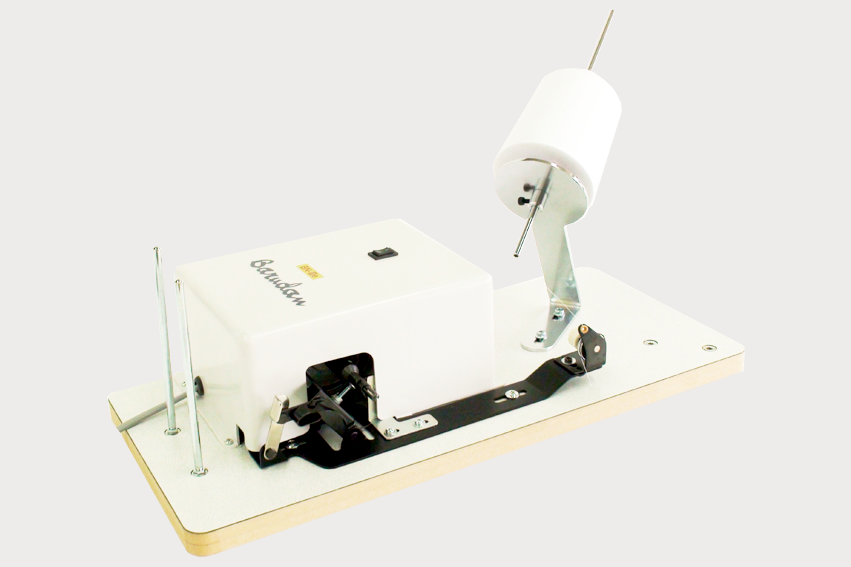

Bobbin Winder (BN-3e)

Machine Specifications

| Maximum Production Capacity | 13 seconds per one cycle / one side |

|---|---|

| Towel Width (mm) |

170~410 |

| Towel Length (mm) |

150~1300 |

| Fret Length (mm) |

25~145 |

| Hem Width (mm) |

10~50 ※1 |

| Stitch Pitch (mm) |

2.5~3.0 |

| Back Stitch (mm) |

about 10mm (1.0~1.5) |

| Power Supply | 3P AC200V 50Hz/60Hz |

| Comsumption (kW) |

0.5 |

| Maximumm Air Consumption | 5kgf/cm² (about 300ℓ/per min. A.N.R. ※2) |

※1 Applicable hem width may vary depending on the thickness and specification of towel materials.

※2 A.N.R: Air with 20 degree, absolute pressure 101.3 kPa, and relative humidity 65%.

・Machines and specifications are subject to change at any time without prior notice.

| Max. Dimension(mm) | Weight(kg) | |

| L | 2550 | 700 |

|---|---|---|

| W | 1100 | |

| H | 1600 |

Machine Dimensions

| Maximum Production Capacity | 13 seconds per one cycle / one side |

|---|---|

| Towel Width (mm) |

170~410 |

| Towel Length (mm) |

150~1300 |

| Fret Length (mm) |

25~145 |

| Hem Width (mm) |

10~50 ※1 |

| Stitch Pitch (mm) |

2.5~3.0 |

| Back Stitch (mm) |

about 10mm (1.0~1.5) |

| Power Supply | 3P AC200V 50Hz/60Hz |

| Comsumption (kW) |

0.5 |

| Maximumm Air Consumption | 5kgf/cm² (about 300ℓ/per min. A.N.R. ※2) |

※1 Applicable hem width may vary depending on the thickness and specification of towel materials.

※2 A.N.R: Air with 20 degree, absolute pressure 101.3 kPa, and relative humidity 65%.

・Machines and specifications are subject to change at any time without prior notice.

| Max. Dimension(mm) | Weight(kg) | |

| L | 2550 | 700 |

|---|---|---|

| W | 1100 | |

| H | 1600 |

・Machines and specifications are subject to change at any time without prior notice.

Option

-

Laser Maker for Label Position ※ for second label position