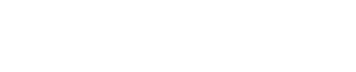

Accessories / Options

A Wide Variety of Optional Devices for Various Embroidery Applications

Automatic Presser Foot Height Adjustment, Bobbin Changer, Automatic Lubtication System, Semi-Automatic Lubrication System, Laser Maker(Cross), Laser Pointer(dot), Loop & Code Device, Boring Device, Needle Punch Device, Signal Tower, Bobbin Winder

Product Lineup

-

“NEW” Bobbin Changer

-

This device automatically replaces the bobbin along with the bobbin case.

It enhances productivity by significantly reducing machine downtime during bobbin replacement.

ex) When replacing all the bobbins in a 20-head embroidery machine:

◎ Operation time by one operator: 6 minutes

◎ Automatic replacement time by bobbin changer: 5 seconds

ex) Bobbin Changer reduce 2 hours and 34 minutes operestion time if you replace bobbins 26 times in 24 hours.

◎ Total operation time by one operator: 2 hours and 36 minutes

◎ Total automatic replacement time by the bobbin changer: 2 minutes and 10 seconds

-

-

“NEW” Automatic Presser Foot Height Adjustment

-

This device automatically adjusts the height of the presser foot, with 15 adjustable levels ranging from 0.5mm to 7.0mm.

-Benefits-

◎ To avoid leaving marks on the fabric from the presser foot

◎ Improves stitch quality for three-dimensional 3D (foam) embroidery

◎ Enables ultra 3D embroidery with high edge using a height of 7mm

-Features-

◎ Height settings for the presser foot can be adjusted individually for each needle bar.

◎ By inserting a presser foot height change signal (PR) into the pattern data, the machine can automatically adjust the presser foot height during operation, allowing for production with different presser foot heights within a single design.

-

-

Automatic Lubtication System

-

Automatically lubricates six parts, including the embroidery heads and hook.

The device automatically lubricates four parts of the embroidery head (needle bar, driving shaft, take up lever, and needle bar connecting rod) and two parts of the bed (lower shaft metal and hook).

It stops the machine automatically at preset intervals or needle counts to lubricate

-

-

Semi-Automatic Lubrication System

-

Luburicates lower shaft metal and hook. By pulling the lever on the oil tank, it dispenses the appropriate amount of oil. By setting the lubrication schedule, the machine can be automatically stopped and a message to lubricate will be displayed.

-

-

Loop & Code Device

-

For simple code and loop stitching. Switch between code stitching and loop stitching with one device. This add-on product can be installed on machines with rotary or slide type heads.

-

-

Boring Device

-

Realizing boring embroidery. It uses a specialized knife to create holes by tearing the fabric fibers.

The holes are then finished with satin stitching to create Bowler embroidery.

-

-

Boring Needle

-

For specialized boring embroidery processing.

By installing a dedicated knife instead of a needle, it tears the fabric fibers to cut the fabric into shapes such as polygons, lemon shapes, and teardrop shapes. After removing the cut fabric, the edges are finished with satin stitching to create the special shapes of Bowler embroidery.

-

-

Needle Punch Device

-

Performing needle punching.

Felt or acrylic fabrics are applied to the back of the main fabric, and special needles are used to pull the fibers of the applied fabric to the surface, creating raised logos or patterns.

-

-

Laser Maker(Cross)

-

Projecting a cross-shaped laser line on the fabric for precise embroidery alignment.

-

-

Laser Pointer(dot)

-

Projecting a dot-type laser to assist with aligning the start position for embroidery.

-

-

Signal Tower

-

Indicating the embroidery machine's status, such as operating, stopping, or error messages, through different light colors and blinking patterns. It offers excellent visibility from a distance, making it easy to monitor the machine's condition.

-

-

Bobbin Winder(BN-IIIe)

-

Bobbin Winder for multi head model

Power Supply:AC100V~AC240V

-

-

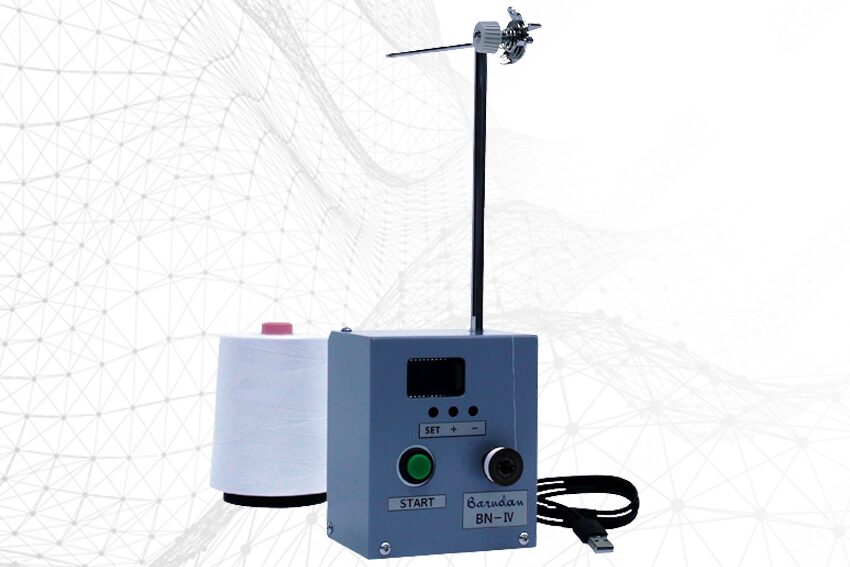

“NEW” Bobbin Winder(BN-IV)

-

Bobbin Winder for single head model

Power suply:USB 3.4A~5.0A Supported

※ A USB converter adapter is required and sold separately.

-